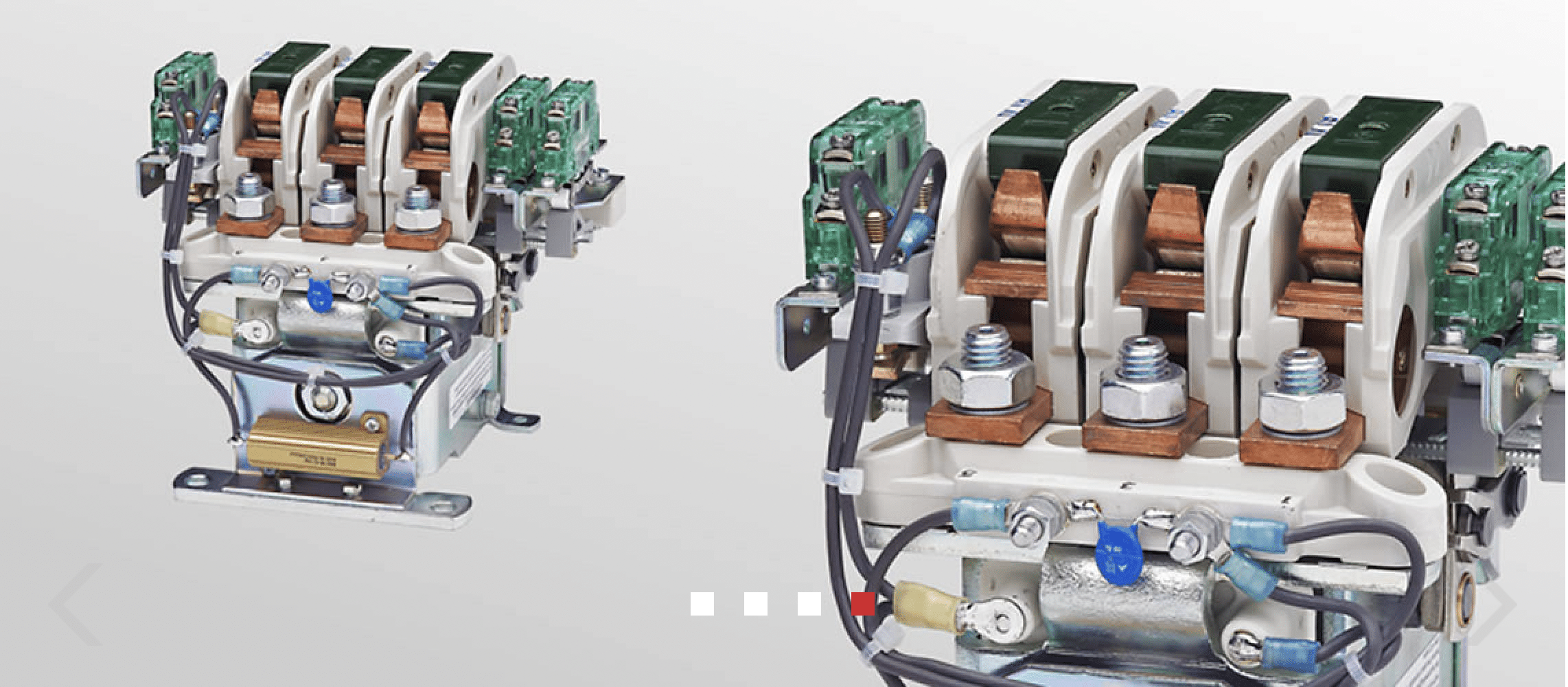

C155, C156, C157 – Multi-pole universally configurable AC and DC contactors

2, 3 and 4 pole cam contactors (NO/NC) up to 1,000 V rated insulation voltage and 300 A continuous current. Electric arc chambers for high power ranges, blowout magnets and arcing chambers for DC applications.

C155

Conventional thermal current up to 300 A

Rated insulation voltage up to 1,000 V

Auxliary Switch: 3x S826

Cam contactors of the series C155, C156 and C157 are 2, 3 and 4 pole switchgears for AC and DC with cam switching elements of the S307 series for 250 or 300 A of continuous current.

The main contacts can be configured as make contacts, break contacts or as combinations of both. For arc quenching at high loads, electric arc chambers can be used; and for DC voltages over 400 volts, arcing chambers with permanent-magnetic blowout should be used.

The switch state of the main contacts can be reported to higher-level control systems and devices with up to 4 auxiliary switches.

Features

The compact contactors C155, C156 and C157 are designed for switching middle and high loads frequently. The switching elements can be replaced individually.

During switch off, an electric arc is ignited between the opening contacts. The current flows on through the ionised air. Permanent magnets drive the ionised air out of the contact zone into the arcing chamber. Here, the electric arc is extended and cooled until it goes out.

For DC voltages of up to 40 volts, a cam switching element with a permanent-magnetic blowout mechanism is to be selected. At voltages of over 40 volts, an electric arc chamber should also be used. At voltages of over 400 volts, the switching element S307 G/N with arcing chamber LK-S307 DC must be used.

The multi-pole cam contactors C155, C156 and C157 can be used in all DC applications up to 1,000 V in which the load does not have to be switched off in both directions:

- Railway technology

- DC drives of machinery

In order to protect the coil of the contactor from excessive heating, a resistor is connected in series with the coil after switch-on.

Optionally, an electronic economy circuit can be chosen. This supplies the required pick-up current for the activation. The current is then regulated down by the electronic economy circuit to the a significantly lower holding current. As a result, the coil becomes less hot and the control power is reduced considerably. The module is attached directly under the contactor.

The switch state of the main contacts can be reported to higher-level control systems and devices through auxiliary contacts.

Break contacts, make contacts or combinations of these are available with the cam-operated switching elements of the S007 series. For safety-related tasks, S800 or S826-series snap-action switches can be chosen: Changeover contacts with double-break contact and mechanical positive opening operation .

The auxiliary switch blocks are installed ex-factory. Quantity and contact type are to be specified during the order.

Specifications

| Type of voltage | DC, AC |

| Main contacts, configuration | 2 x /3 x /4 x NO and/or NC |

| Nominal voltage Un | 450 V |

| Rated insulation voltage Ui | 630 V |

| Conv. thermal current Ith | 250, 300 A |

| Making capacity, resistive T = 0 ms | 900, 1,400 A |

| Contact material main contacts | AgSnO2 |

| Aux. contact | 4 cam switch elements or snap switches max. |

| Coil voltage Us | 24, 48, 60, 72, 96, 110, 120, 220 V DC |

| Coil tolerance | -30% … +25% |

| Coil power consumption | Pull-in: approx. 200 W / hold: 38 W |

| IP rating (IEC 60529) | IP00 |

| Mechanical endurance | 2 million operating cycles |

| Temperature range | -25 °C … +70 °C |

| Storage temperature | -40 °C … +80 °C |

| Weight | approx. 4,900 |

What do you want to do?

Do you have questions about this product?

Bookmark product