Contactors for critical applications

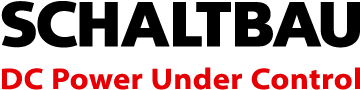

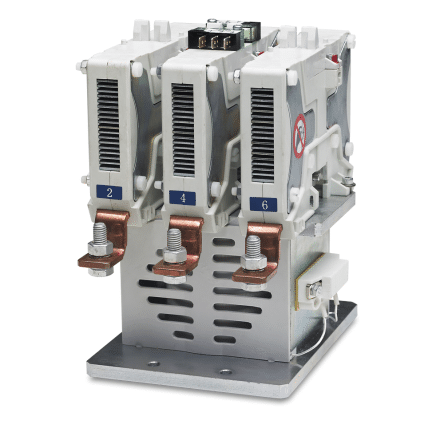

AC and DC contactors up to 4,800 V and 2,000 A

With the the introduction of DC networks in manufacturing, as well as the rapid growth of renewable energies and the electric automobile motor industry, the switching of high DC loads is gaining in significance and underscoring the need for high-quality DC contactors. Building upon our experience in railway technology, Schaltbau produces highly reliable, outstanding contactors for all fields of use in which a load circuit has to be switched on and disconnected securely. Designed to IEC specifications, our wide variety of AC and DC contactors in stock range from contactors for low-voltage devices, such as batteries, through to high-voltage power contactors up to 4,800 V and 1,100 A. We develop DC contactors for, among other uses, industrial storage systems, battery test systems, car batteries and electrical bus motors.

A DC or AC contactor (or switching contactor) is an electrically or electromagnetically (in special applications also pneumatically) operated switch for large electrical loads. The main contact is located inside the main circuit of the device, while auxiliary contact is found inside an auxiliary circuit and actuated mechanically by the switching device – serving to reduce coil current after the device switches off. The contactor includes a coil input (driven by DC or AC supply), with the coil energized by the same voltage as the motor the device is controlling or controlled with a lower coil voltage.

Whereas a general-purpose relay is nor designed to be directly connected to high-current load devices, both DC contactors and AC contactors can switch large loads remotely via control lines. When a control voltage is applied to the coil of the instrument, the magnetic field pulls an electrical bridge into an active state – the main contacts close. Without control voltage, springs in the contactor restore the initial state of the load circuit – the contact path is open again.

Unlike a general-purpose relay, contactors galvanically isolate the electrical drive train from the power supply when it is switched off, with an auxiliary contact reducing coil current after the contactor closes.

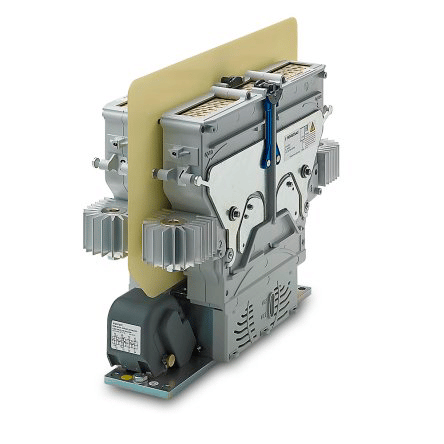

If switching off takes place under load, an electric arc is generated in the contactor. In DC voltage applications, extinguishing this arc is comparatively challenging, as no zero crossing of the voltage occurs here. Our DC contactors have effectively overcome this challenge, making arc suppression one of our products’ most notable attributes.

The electric arc in the contactor produced can only be controlled if different effects interact skillfully. Only then can short arc lifetimes – and thus fast switch-off times – be achieved. Thanks to our patented contactor process, this is a key feature of our DC contactors.

The formation of this so-called switching arc has two main effects: Firstly, current continues to flow despite the contacts being open, as the plasma has a high electrical conductivity. And secondly, very high temperatures of up to 20,000 Kelvin occur, which can cause damage to the contacts of the DC contactor as well as to surrounding system parts.

Unlike lower-powered relays, various measures are present in our DC contactor to counteract this. It is particularly important to move the arc away from the actual contact surfaces and to extinguish it. This is mainly done by means of an arcing chamber in which the electric arc is elongated, cooled and thus extinguished.

The arcing chamber is thus the central functional unit in DC power contactors.

Find contactors for your application

Reset all

Reset all