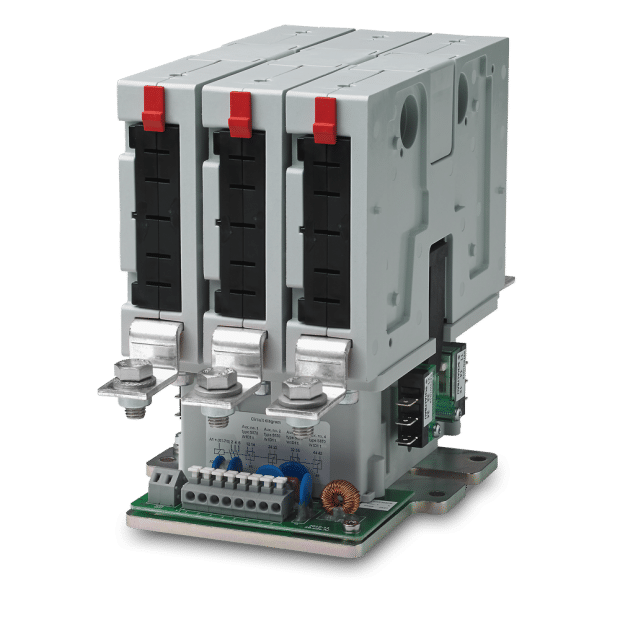

Contactors for permanent-magnetic synchronous motors

Modern electric drives require flexible switchgear to that they can work efficiently and safely. New challenges are constantly arising, especially with synchronous motors operating at frequencies above 50 Hz.

Switching arcs are in principle a well-studied phenomenon in electrical engineering. However, modern drives with permanent-magnetic synchronous machines, which are operated with converters at frequencies sometimes significantly above 50 Hz, present a new challenge for switching technology. We have taken up this challenge with the development of our new CF contactors and can now offer a powerful solution for these applications.

This is what you will learn in this article:

Permanent-magnetic synchronous motors as a direct drive

Cage induction (asynchronous) motors combined with gearboxes were used as the drives in the first generation of high speed trains. This combination of motor and gearbox has the disadvantage that the drive motor is very noisy due to the necessary forced air ventilation. In addition, the gearbox results in high procurement and maintenance costs as well as increased space requirements and weight. The use of permanent-magnetic synchronous motors (PSM) as a direct drive means that a gearbox is no longer needed. This results in significantly lower noise emissions, weight and maintenance expense. With these drive variants, the speed is directly regulated via the frequency of the supplying inverter.

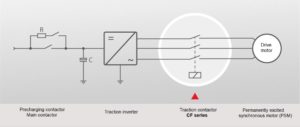

Nevertheless, permanent-magnetic synchronous motors have a decisive disadvantage: if the rotating field fails, for example if there is an inverter fault, the drive immediately functions as a generator feeding the power back into the supply system in an uncontrolled manner. In the event of a fault, this must be prevented under all circumstances. To do so, the electrical connection between inverter and motor must be interrupted by contactors.

Block diagram of a drive motor

With PSMdrives, a contactor must be able to reliably disconnect an electric motor, in order to prevent uncontrolled power feedback in the event of a fault.

Switching technology for high currents and voltages

Contactors are electrically or electromagnetically (in special applications also pneumatically) actuated switches for high electrical outputs. Contactors were developed for remote switching of large consumers via relatively small cross-section control cables. When a control voltage is applied to the contactor coil, the magnetic field switches a bridge circuit to an active state – the main contacts close. In the absence of a control voltage, springs recreate the initial state, the contact path is once again open circuit.

In the presence of high currents and voltages, the ionisation threshold of air can be exceeded due to the high current density at the contact point when switching occurs. A plasma (a gas comprising ionised air molecules and free electrons) is then formed between the contact points. The formation of this switching arc has two key consequences: Firstly, despite open contacts, current continues to flow because the plasma has a high electrical conductivity. Secondly, very high temperatures of up to 20,000 K occur, easily capable of causing damage to the contacts of the contactor, as well as to the surrounding system components. Due to the zero crossing of the voltage which, at a mains frequency of 50 Hz, occurs no more than 20 milliseconds later, this can be quenched in a relatively simple manner. However, problems arise in switching inductive loads because now the voltage and current are no longer in phase. Whatever the case, where there are high-energy electric arcs associated with relatively high voltages and currents, damage to the contactor or the entire system can occur. Therefore, various measures must be implemented to counteract this.

Loop effect extinguishes arcs even at high frequencies

Conventionally designed contactors work with permanent magnets or electromag-netic blow-out coils, so that the electric arcs are driven quickly out of the contact area into the arc control device. At a frequency of 50 Hz, a period of 20 ms re-mains for the electric arc to be switched to the modulator and for the blow-out coils to activate driving the electric arcs into the arcing chamber. As PSM drives operate at higher frequencies, the prerequisites are changed. At 400 Hz, the time window is only 1.5 ms, a period that is too short for many contactors to be able to switch the electric arc. Moreover, there are other effects that must be taken into consideration:

Firstly, the more frequent magnetising and demagnetising at 400 Hz generates increased heat, which first and foremost strongly heats the metallic ancillary components of a conventional contactor, such as pole plates and magnetic cores. Any inductances that exist result in additional time constants, causing a phase shift between the voltage and current zero crossings. In this way, at the time of the voltage zero crossing, the current may still be so high that immediate reignition of the electric arc occurs. Consequently, conventional contactors are not suitable for switching higher frequencies.

In order that higher frequencies can also be reliably switched, Schaltbau is offering new contactors in its CF series. These contactors enable the safe and reliable high-frequency switching of inverter-supplied AC drives (PSM). The high switching performance results amongst other things from the double contact breaking per switching chamber. Moreover, the CF series has a high short-circuit making capacity of 4 kA and a high short-time withstand current of up to 5 kA.

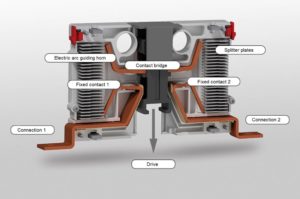

Schaltbau uses the loop effect principle for arc quenching in this contactor series. Current-carrying conductors form a magnetic field, and analogously switching arcs form a magnetic field during their arching period. Based on the special geometry of the fixed contacts and the contact bridge a blow-out effect is created which drives the arc away from the contact zone in the direction of the arcing chamber. Then it is pulled in by the ferromagnetic splitter plates. The switching arc switches to the splitter plates and is then lengthened, cooled and quenched, without leaving the contactor (Figure 2). The newly developed switching chambers can be configured as normally open contacts, normally closed contacts or in combination as changeover switches. Various arcing chamber elements from plastic, steel or ceramic are available so that the contactor can be designed to exactly match the switching requirements of the application.

A special electronic economy circuit controls the setting time of the contactor inde-pendent of the applied coil voltage through a PWM controller. It makes a high pull-in power available but reduces the power consumption in holding operation, which results in a reduction in heat losses. Due to the integrated temperature compensation, safe pull-in operation is reliably ensured under all required ambient conditions. In this way, the temperature problem associated with conventional contactors is reliably avoided.

Schematic representation of a CF series extinguishing chamber

Modular construction kit for every application

To cover a wide range of currents and voltages and simultaneously offer a specific contactor solution for special applications, the CF series is designed based on modular building blocks. One to six-pole variants for unidirectional direct current, bidirectional direct current and alternating current up to several hundred hertz can be modularly configured – thus the contactor can be optimally matched to the customer application. The series carries currents up to 400 A per switching element (in a parallel circuit configuration up to 1,800 A) for AC or DC voltages of up to 3,000 V. The user is able to configure a contactor precisely to match their application and in this way can optimise their application both electrically and in terms of design volume and costs (Figure 3). Naturally, the CF-series contactors fulfil all the standards and regulations for railway (including EN 60077) and industrial use (including EN 60947).